Self-closing door hinges are an essential feature for both residential and commercial properties. They enhance the convenience of automatic door closure, ensuring energy efficiency, safety, and security. However, like any mechanical component, self-closing door hinges require regular maintenance to ensure they operate smoothly and last for years.

In this comprehensive guide, we’ll cover everything you need to know about maintaining self-closing door hinges, including common issues, preventive care, and step-by-step instructions for maintaining different types of self-closing hinges. Whether you’re a homeowner, building manager, or DIY enthusiast, this guide will give you the tools and knowledge to extend the lifespan of your hinges and ensure optimal functionality.

What Are Self-Closing Door Hinges?

Self-closing door hinges are hinges designed with a built-in mechanism that automatically closes the door after it’s been opened. They’re commonly used in areas that require fire-rated doors, as well as in spaces that need doors to remain closed for security or climate control purposes. These hinges typically rely on tension springs or hydraulic systems to perform their function.

Benefits of Self-Closing Door Hinges

Before we dive into maintenance, it’s helpful to understand the benefits of these hinges, which underscore why proper care is crucial:

Fire Safety: Self-closing hinges are often required for fire-rated doors. By automatically closing doors in the event of a fire, they can prevent the spread of flames and smoke, which can save lives and property.

Energy Efficiency: In climate-controlled environments, these hinges help keep doors closed to maintain consistent temperatures, reducing energy costs.

Security: Self-closing hinges are common in high-security areas such as offices, schools, and commercial buildings, where doors must remain closed for safety and access control.

Convenience: For households with pets or small children, self-closing hinges ensure that doors aren’t left open unintentionally, reducing the risk of accidents.

Types of Self-Closing Door Hinges

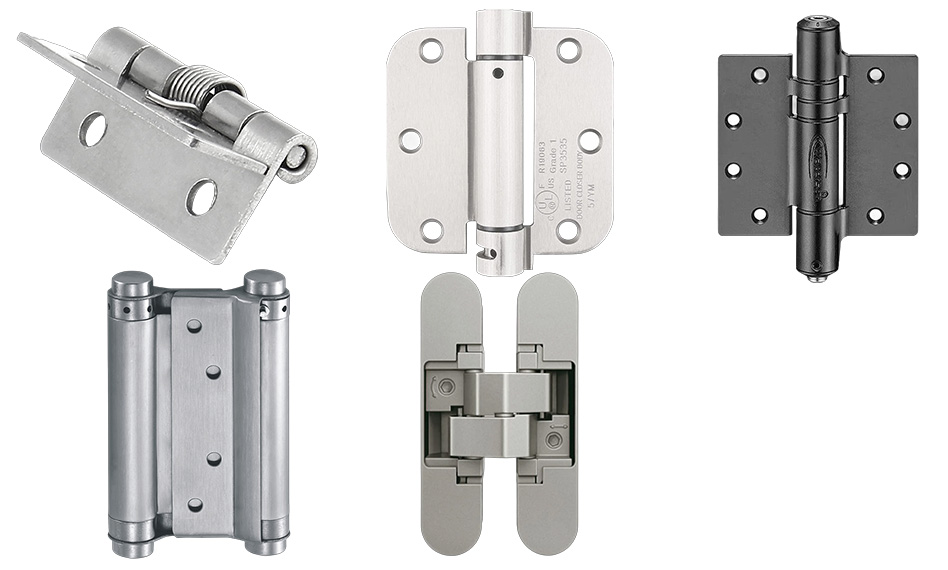

Not all self-closing hinges are the same. Depending on the design and application, there are several types of self-closing door hinges available, each requiring slightly different maintenance approaches. The main types include:

Spring-Loaded Hinges: These hinges rely on tension springs to pull the door back to its closed position. They are commonly used in residential and commercial doors.

Hydraulic Self-Closing Hinges: These use a hydraulic piston to control the door’s motion, ensuring a smooth and controlled closure. They are often found in heavier commercial doors.

Double-Action Hinges: These hinges allow a door to swing open in both directions and then close automatically, commonly used for kitchen or restaurant doors.

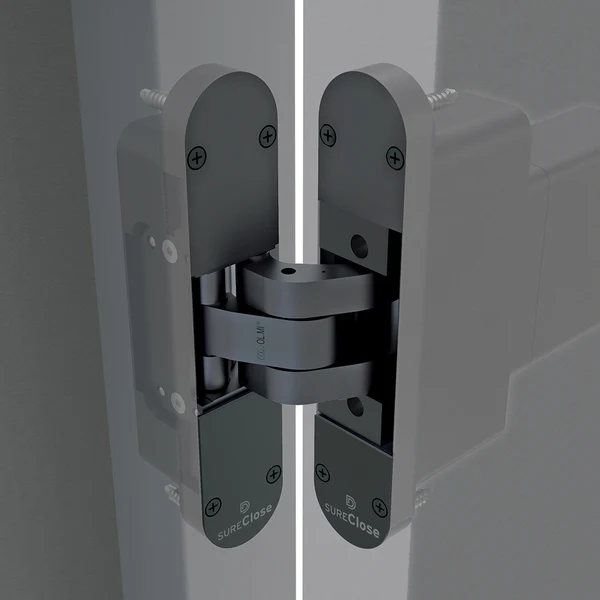

Concealed Self-Closing Hinges: These hinges are hidden within the door and frame, providing an aesthetic advantage while offering the same functionality as standard self-closing hinges.

Common Maintenance Issues

Over time, self-closing door hinges can develop a range of issues that may impact their performance. Recognizing these issues early is crucial for effective maintenance:

Hinges Becoming Stiff or Jammed: This is usually caused by dirt, debris, or lack of lubrication. Hinges can also become misaligned due to improper installation or regular wear and tear.

Door Slams Shut: A common issue with self-closing hinges is that the door closes too quickly, which can be both dangerous and damaging. This problem typically occurs due to excessive spring tension or failure in the hydraulic mechanism.

Door Doesn’t Fully Close: If the hinge loses tension, the door may fail to close completely. In hydraulic hinges, this can also happen if the hydraulic fluid levels are low or the mechanism is damaged.

Squeaking or Grinding Noise: This is often a sign that the hinges need lubrication or that they’ve accumulated dirt and debris.

Loose Hinges: If the screws holding the hinges in place become loose, the door may sag or fail to close properly.

Preventive Maintenance for Self-Closing Hinges

Regular maintenance is essential to prevent these common issues from occurring. The following preventive measures will help ensure that your hinges operate smoothly and last for years.

1. Cleaning the Hinges

Dust, dirt, and grime can accumulate around hinges over time, causing them to become stiff or jammed. Here’s how to clean your self-closing hinges properly:

Step 1: Remove any visible dust and debris using a dry cloth or a small brush.

Step 2: For more thorough cleaning, use a damp cloth and a mild detergent to clean around the hinge. Be careful not to get moisture into the spring or hydraulic mechanism.

Step 3: Dry the hinges completely before moving on to lubrication.

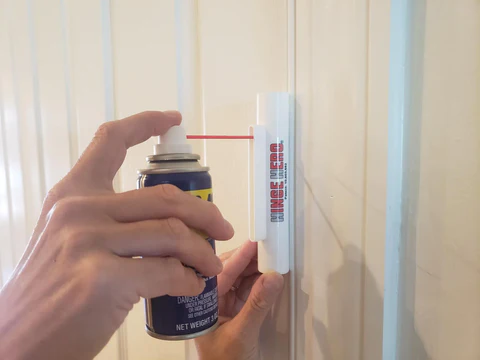

2. Lubricating the Hinges

Lubrication is one of the most important aspects of hinge maintenance, especially for spring-loaded and hydraulic hinges. Proper lubrication reduces friction, prevents squeaking, and extends the lifespan of the hinge.

Step 1: Choose the right lubricant. Use a silicone-based lubricant or a light machine oil. Avoid heavy oils that can attract dirt and dust.

Step 2: Apply the lubricant to the pivot points of the hinge and any exposed moving parts.

Step 3: Open and close the door several times to distribute the lubricant evenly.

Step 4: Wipe away any excess lubricant with a clean cloth to prevent dirt accumulation.

3. Checking the Tension

For spring-loaded hinges, maintaining the correct tension is critical to ensure the door closes properly without slamming. Here’s how to check and adjust the tension:

Step 1: Locate the tension adjustment mechanism, which is usually a small pin or screw on the hinge.

Step 2: Test the door to see if it closes too quickly or too slowly.

Step 3: If the door closes too quickly, reduce the tension by turning the adjustment screw or pin counterclockwise.

Step 4: If the door doesn’t close all the way, increase the tension by turning the adjustment screw clockwise.

Step 5: Test the door again and repeat the process until the desired tension is achieved.

4. Inspecting for Wear and Tear

Regular inspections help catch early signs of wear and tear before they become major problems. At least once a year, check your self-closing hinges for the following issues:

Loose Screws: Tighten any loose screws on the hinge plates.

Worn Springs: For spring-loaded hinges, inspect the springs for signs of wear or rust. If the spring is damaged, it may need to be replaced.

Hydraulic Leaks: For hydraulic hinges, check for leaks or signs of hydraulic fluid around the hinge. Leaks indicate that the hinge needs to be repaired or replaced.

Step-by-Step Maintenance Guide

Now that you understand the importance of preventive maintenance, let’s walk through a detailed maintenance process for each type of self-closing door hinge.

Maintaining Spring-Loaded Self-Closing Hinges

Spring-loaded self-closing hinges are commonly used in both residential and commercial doors. These hinges rely on a built-in spring mechanism to automatically pull the door back to its closed position after it has been opened. Proper maintenance of these hinges involves regular cleaning, lubrication, and tension adjustment.

Materials Needed:

Screwdriver

Cleaning cloth

Silicone-based lubricant or light machine oil

Small brush

Allen wrench (if required for tension adjustment)

Step 1: Clean the Hinges Begin by cleaning the hinge area to remove any dirt, dust, or debris that may have accumulated. Dirt and grime can cause the hinges to stiffen or even jam, reducing their effectiveness.

Use a dry cloth or a small brush to remove dust from the hinge surface.

For a deeper clean, dampen the cloth slightly with water and wipe around the hinge. Be careful not to get water into the internal mechanism of the hinge, especially where the spring is located, as moisture can lead to rust and damage.

Step 2: Lubricate the Hinges Lubrication is critical to ensure the smooth operation of spring-loaded hinges. Without proper lubrication, the hinge may squeak or grind when opening and closing, and over time, the friction may wear down the moving parts.

Select a silicone-based lubricant or light machine oil, which will reduce friction without attracting dirt.

Apply a small amount of lubricant directly to the pivot points of the hinge, where the parts rotate or move.

After applying the lubricant, open and close the door several times to allow the lubricant to spread evenly through the mechanism.

Wipe away any excess lubricant to prevent dust from sticking to the hinge.

Step 3: Adjust the Tension Spring-loaded hinges rely on adjustable tension to control the speed and force with which the door closes. If the door slams too quickly or doesn’t close fully, adjusting the tension will correct these issues.

Locate the tension adjustment pin or screw on the hinge. This is typically a small mechanism that allows you to increase or decrease tension.

Use the appropriate tool (an Allen wrench, screwdriver, or tension pin) to adjust the tension.

If the door slams shut, reduce the tension by turning the adjustment counterclockwise.

If the door fails to close completely, increase the tension by turning the adjustment clockwise.

Test the door by opening and closing it after each adjustment to find the optimal tension setting.

Step 4: Tighten Screws Over time, screws securing the hinge to the door or the door frame may become loose, leading to poor alignment or sagging.

Use a screwdriver to check and tighten all the screws on the hinge plate.

If any screw holes are stripped (meaning the screws no longer hold tightly), consider using longer screws or filling the holes with wood filler before re-installing the screws to ensure a secure fit.

Maintaining Hydraulic Self-Closing Hinges

Hydraulic self-closing hinges offer smoother, more controlled closure thanks to a hydraulic piston that regulates the door’s speed and motion. These hinges are often found in commercial environments and on heavy-duty doors. Hydraulic hinges require specific care, particularly if leaks or loss of hydraulic fluid are involved.

Materials Needed:

Screwdriver

Silicone-based lubricant (if recommended by the manufacturer)

Cleaning cloth

Small brush

Manufacturer’s manual for adjustment instructions

Step 1: Clean the Hinges Just like spring-loaded hinges, hydraulic hinges need to be kept clean to avoid operational issues.

Use a dry cloth to remove dirt, dust, and debris from the hinge surface.

For areas with more grime, use a damp cloth with mild soap to clean around the hinge, taking care to avoid moisture near the hydraulic cylinder.

Step 2: Check for Hydraulic Fluid Leaks One of the most common issues with hydraulic hinges is fluid leakage. If hydraulic fluid is leaking, the hinge will lose its ability to control the door’s speed and may need to be repaired or replaced.

Inspect the hinge closely for signs of fluid around the piston or along the hinge body.

If you notice hydraulic fluid, consult the manufacturer’s guidelines for possible repairs or replacements.

Step 3: Lubricate the Hinge (If Necessary) Some hydraulic hinges may require periodic lubrication on their moving parts, though many are designed to operate without additional lubrication.

If the manufacturer recommends lubrication, apply a silicone-based lubricant to the pivot points.

Avoid applying lubricant directly to the hydraulic mechanism unless explicitly instructed by the manufacturer.

Step 4: Adjust the Hydraulic Mechanism Hydraulic self-closing hinges often have adjustable settings to control the speed at which the door closes. This feature prevents slamming and ensures a smooth operation.

Locate the adjustment valve on the hinge. This is usually a small screw or dial that controls the hydraulic flow.

Turn the adjustment screw clockwise to slow down the closing speed if the door is slamming.

Turn the adjustment screw counterclockwise to speed up the door if it’s closing too slowly.

Test the door’s movement after each adjustment to ensure a smooth and controlled closure.

Maintaining Double-Action Self-Closing Hinges

Double-action self-closing hinges allow a door to swing open in both directions before returning to a closed position. These hinges are popular in commercial kitchens, restaurants, and other areas where doors need to open and close in both directions. They are slightly more complex than standard spring-loaded hinges, as they must maintain balance for both swings.

Materials Needed:

Silicone-based lubricant

Screwdriver

Cleaning cloth

Allen wrench (for tension adjustment)

Step 1: Clean the Hinges Double-action hinges are prone to collecting dirt and debris, especially in high-traffic areas. Regular cleaning is essential to maintain smooth operation.

Use a dry cloth to remove surface dust and debris.

For heavier grime, use a damp cloth to wipe down the hinges, taking care to avoid moisture getting into the internal mechanisms.

Step 2: Lubricate the Hinges Just like other self-closing hinges, double-action hinges need lubrication to reduce friction and ensure smooth movement.

Apply a silicone-based lubricant to the pivot points where the hinge rotates.

Open and close the door several times in both directions to distribute the lubricant evenly.

Be sure to wipe off any excess lubricant to prevent dust from sticking to the hinges.

Step 3: Adjust the Tension for Both Swings Double-action hinges typically have tension adjustments for both directions (inward and outward swing). If the door is closing too quickly or too slowly in either direction, you can adjust the tension to correct the problem.

Locate the tension adjustment mechanism for both swings (inward and outward).

Use an Allen wrench or screwdriver to adjust the tension. Tighten the tension for each swing direction by turning the adjustment screw clockwise to slow the door down or counterclockwise to speed it up.

Test the door after each adjustment to ensure balanced and controlled movement in both directions.

Step 4: Tighten Screws and Bolts Loose screws or bolts can cause alignment issues, which will affect the functionality of the door.

Check all screws and bolts securing the hinges to the door and the frame.

Use a screwdriver to tighten any loose screws, and replace any damaged screws if necessary.

Maintaining Concealed Self-Closing Hinges

Concealed self-closing hinges, often used in cabinetry or flush doors, are hidden within the door and frame for aesthetic purposes. Despite their hidden nature, these hinges still require regular maintenance to function effectively.

Materials Needed:

Small brush

Screwdriver

Cleaning cloth

Silicone-based lubricant

Step 1: Clean the Hinges Since concealed hinges are hidden, they may not collect as much dust, but they still need to be kept clean to prevent operational issues.

Use a small brush to clean out any dirt or debris from the hinge cavity.

If needed, use a damp cloth to clean the hinge, ensuring the area is fully dried afterward.

Step 2: Lubricate the Hinge Concealed hinges can benefit from lubrication, especially around the moving parts and pivot points.

Apply a small amount of silicone-based lubricant to the areas where the hinge pivots.

Move the door back and forth to spread the lubricant and ensure smooth motion.

Wipe away any excess lubricant.

Step 3: Check and Adjust the Tension If the hinge has adjustable tension, check to see if the door closes properly. If it’s closing too quickly or not fully closing, adjust the tension using the manufacturer’s recommended tools.

Use an Allen wrench or a tension pin to make adjustments.

Test the door after each adjustment to find the optimal setting.

Step 4: Tighten Screws Make sure all screws holding the hinge in place are tight. Loose screws can cause misalignment and prevent the door from closing correctly.

Tighten any loose screws with a screwdriver.

If any screws are stripped or damaged, replace them with new ones to ensure a secure fit.

Troubleshooting Common Issues

Even with regular maintenance, self-closing door hinges may encounter occasional problems. Here are some common issues and how to troubleshoot them:

1. Door Slams Shut

If your door slams shut, the tension is likely set too high, or the hydraulic mechanism needs adjustment.

For spring-loaded hinges: Reduce the tension by turning the adjustment screw counterclockwise.

For hydraulic hinges: Adjust the hydraulic mechanism to slow the door’s closure speed.

2. Door Doesn’t Fully Close

If the door doesn’t close completely, the tension may be too low, or the hinge may be misaligned.

For spring-loaded hinges: Increase the tension by turning the adjustment screw clockwise.

For hydraulic hinges: Check for leaks and adjust the hydraulic settings as needed.

3. Squeaking Hinges

Squeaking is a sign that the hinges need lubrication.

Apply a small amount of silicone-based lubricant to the pivot points of the hinge.

Wipe away any excess lubricant to prevent dirt accumulation.

4. Loose or Sagging Door

If the door appears to sag or the hinge feels loose, tighten all screws securing the hinge to the door and frame.

Use a screwdriver to tighten any loose screws.

If the screw holes are stripped, consider using longer screws or adding wood filler to create a more secure fit.

When to Replace Self-Closing Hinges

Despite regular maintenance, self-closing door hinges will eventually wear out and need replacement. Here are some signs that it’s time to replace your hinges:

Excessive Wear on the Spring: If the spring in a spring-loaded hinge is damaged or worn out, the hinge will no longer function properly.

Hydraulic Fluid Leaks: Hydraulic hinges that are leaking fluid may need to be replaced, as they will lose their ability to control the door’s closure.

Misalignment: If the hinge has become significantly misaligned and can’t be adjusted, it may need to be replaced to restore proper door function.

Conclusion

Proper maintenance of self-closing door hinges is essential for ensuring their longevity and optimal performance. Whether you’re dealing with spring-loaded, hydraulic, or double-action hinges, regular cleaning, lubrication, and tension adjustments are key to keeping your doors operating smoothly. By following the preventive care and troubleshooting steps outlined in this guide, you’ll be able to extend the lifespan of your hinges, improve safety, and maintain the overall efficiency of your doors.

Remember, while self-closing door hinges are built to last, they aren’t immune to wear and tear. Keeping up with regular maintenance will not only help you avoid costly repairs but also ensure that your doors function properly for years to come.